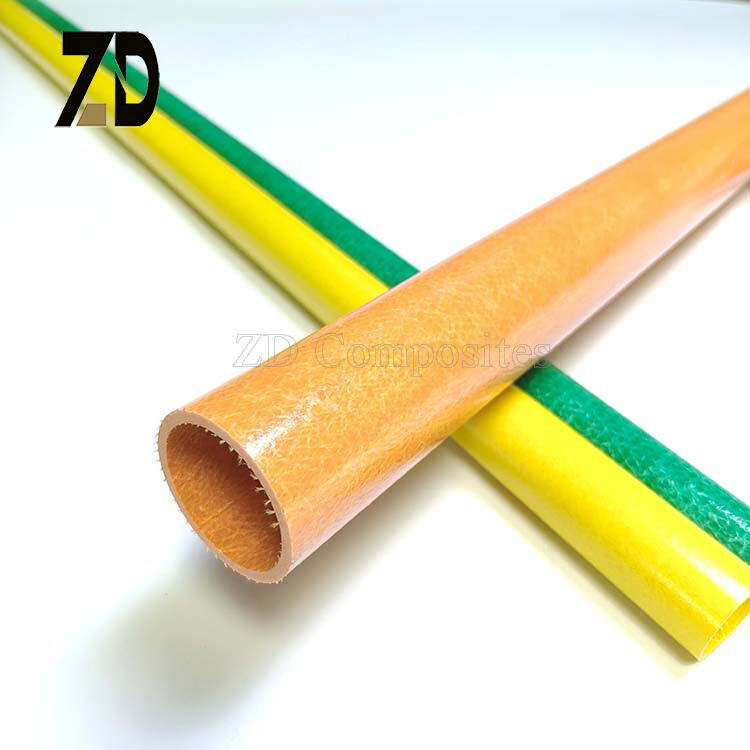

Modern industrial applications demand materials that deliver exceptional performance across multiple criteria including strength, durability, corrosion resistance, and cost-effectiveness. When selecting tubular structures for engineering projects, professionals often compare three primary options: plastic, metal, and fiberglass tubes. While each material has its merits, fiberglass tube technology has emerged as the superior choice for numerous applications due to its unique combination of properties that outperform traditional materials in critical performance metrics.

The evolution of composite materials has revolutionized the tubular product industry, with fiberglass tubes representing a significant advancement over conventional alternatives. These engineered products combine glass fiber reinforcement with polymer resin systems to create structures that offer remarkable versatility across diverse industrial sectors. Understanding the comparative advantages of fiberglass tube construction versus plastic and metal alternatives is essential for engineers, procurement specialists, and project managers seeking optimal material solutions.

Mechanical Properties and Structural Performance

Strength-to-Weight Ratio Advantages

The exceptional strength-to-weight ratio of fiberglass tube construction represents one of its most significant advantages over plastic and metal alternatives. Fiberglass tubes typically exhibit tensile strengths ranging from 200 to 800 MPa while maintaining densities approximately 75% lower than steel. This remarkable characteristic enables engineers to design lighter structures without compromising load-bearing capabilities, resulting in reduced foundation requirements and simplified installation procedures.

Compared to plastic tubes, which often struggle with structural applications due to limited strength properties, fiberglass tube assemblies can handle substantial mechanical loads while maintaining dimensional stability. The continuous glass fiber reinforcement provides directional strength properties that can be optimized during manufacturing to meet specific application requirements. This engineering flexibility is rarely achievable with conventional plastic or metal tubing systems.

Fatigue Resistance and Durability

Long-term performance under cyclic loading conditions demonstrates another area where fiberglass tube technology excels beyond traditional materials. The composite structure inherently resists fatigue crack propagation, a common failure mode in metal tubes subjected to repeated stress cycles. Unlike metal tubes that experience progressive fatigue damage, fiberglass tubes maintain their structural integrity throughout extended service periods.

The fatigue resistance of fiberglass tube products stems from their composite construction, where load distribution occurs across multiple fiber orientations rather than through homogeneous material structures. This characteristic proves particularly valuable in applications involving vibration, thermal cycling, or dynamic loading conditions where metal tubes might develop stress concentrations and eventual failure.

Environmental Resistance and Chemical Compatibility

Corrosion Immunity

Perhaps the most compelling advantage of fiberglass tube systems lies in their complete immunity to electrochemical corrosion processes that plague metal alternatives. While steel, aluminum, and other metal tubes require protective coatings, cathodic protection, or regular maintenance to combat corrosion, fiberglass tubes maintain their properties indefinitely when exposed to moisture, salt water, and most chemical environments.

This corrosion resistance translates directly into reduced lifecycle costs and enhanced reliability for infrastructure projects. Marine applications, chemical processing facilities, and underground installations particularly benefit from fiberglass tube systems that eliminate the need for expensive corrosion protection measures and frequent replacement schedules associated with metal alternatives.

Chemical Resistance Capabilities

The chemical resistance properties of fiberglass tube construction surpass both plastic and metal alternatives in many industrial environments. While plastic tubes may soften, crack, or degrade when exposed to organic solvents or elevated temperatures, and metal tubes suffer from chemical attack, fiberglass tubes maintain their structural properties across broad chemical compatibility ranges.

Resin selection during fiberglass tube manufacturing allows customization of chemical resistance properties to match specific environmental conditions. Vinyl ester, epoxy, and specialized resin systems can be employed to create tubes that withstand exposure to acids, bases, solvents, and other aggressive chemicals that would rapidly degrade alternative materials.

Thermal Performance and Dimensional Stability

Temperature Cycling Resistance

Thermal expansion coefficients of fiberglass tube materials closely match those of concrete and other construction materials, providing superior dimensional stability compared to metal or plastic alternatives. This thermal compatibility reduces stress development in composite structures and eliminates the need for complex expansion joint systems that metal installations often require.

The low thermal conductivity of fiberglass tube construction also provides excellent insulation properties, preventing condensation formation and reducing energy losses in temperature-controlled applications. Metal tubes, with their high thermal conductivity, often require additional insulation systems that increase installation costs and maintenance requirements.

High-Temperature Applications

Advanced fiberglass tube formulations can withstand continuous operating temperatures exceeding 200°C, significantly outperforming most plastic alternatives while avoiding the thermal expansion issues associated with metal tubes. The glass fiber reinforcement maintains its properties at elevated temperatures, providing structural stability that plastic tubes cannot match.

Fire resistance characteristics of fiberglass tube systems also exceed those of plastic alternatives, with many formulations achieving self-extinguishing properties and low smoke generation ratings required for building code compliance and safety applications.

Manufacturing Versatility and Customization

Geometric Flexibility

Pultrusion and filament winding manufacturing processes enable fiberglass tube production in virtually unlimited geometric configurations, wall thickness variations, and dimensional specifications. This manufacturing flexibility surpasses the limitations of metal forming processes and plastic extrusion capabilities, allowing engineers to specify optimal tube geometries for specific applications.

Complex cross-sectional profiles, integrated connection features, and variable wall thickness designs are readily achievable with fiberglass tube manufacturing techniques. These capabilities enable system optimization and cost reduction through part consolidation that is often impossible with conventional materials.

Property Customization

The composite nature of fiberglass tube construction allows precise tailoring of mechanical, thermal, and electrical properties during manufacturing. Fiber orientation, resin selection, and reinforcement patterns can be optimized to create tubes with anisotropic properties that maximize performance for specific loading conditions and environmental requirements.

This customization capability represents a fundamental advantage over metal and plastic tubes, which offer fixed material properties that cannot be modified to suit application-specific requirements. Engineers can specify fiberglass tube designs that deliver optimal performance while minimizing material usage and cost.

Economic Considerations and Lifecycle Value

Installation Cost Benefits

The lightweight nature of fiberglass tube systems significantly reduces installation costs compared to metal alternatives. Reduced crane requirements, simplified handling procedures, and faster installation times contribute to lower project costs and shortened construction schedules. These benefits become particularly significant for large-scale installations where handling and transportation costs represent substantial project expenses.

Non-conductive properties of fiberglass tube materials also eliminate the need for electrical isolation systems required with metal alternatives in many applications. This characteristic simplifies installation procedures and reduces material costs while improving system reliability and safety performance.

Maintenance and Lifecycle Economics

Long-term economic advantages of fiberglass tube systems stem from their exceptional durability and minimal maintenance requirements. Unlike metal tubes that require periodic inspection, coating renewal, and corrosion mitigation measures, fiberglass tubes maintain their properties throughout extended service periods with minimal intervention.

The absence of galvanic corrosion, fatigue crack development, and environmental degradation eliminates many common failure modes that affect metal and plastic tube systems. This reliability translates directly into reduced maintenance costs, improved system availability, and enhanced operational efficiency throughout the product lifecycle.

Electrical and Electromagnetic Properties

Dielectric Characteristics

Fiberglass tube materials exhibit excellent dielectric properties that make them ideal for electrical applications where metal tubes would create conduction paths or electromagnetic interference issues. The non-conductive nature of fiberglass tubes eliminates grounding requirements and electrical safety concerns associated with metal alternatives.

These electrical properties prove particularly valuable in telecommunications, power transmission, and electronic equipment applications where electromagnetic transparency or electrical isolation is required. Plastic tubes may offer similar electrical properties but lack the mechanical strength and environmental resistance of fiberglass tube systems.

Electromagnetic Transparency

The electromagnetic transparency of fiberglass tube construction enables their use in applications where radio frequency signals must pass through structural elements without attenuation or reflection. This characteristic provides significant advantages in telecommunications infrastructure, radar systems, and antenna support applications where metal tubes would interfere with signal transmission.

Specialized fiberglass tube formulations can be engineered to provide specific electromagnetic properties, including controlled dielectric constants and loss factors for high-frequency applications. This level of electromagnetic property control is not achievable with conventional metal or plastic tube materials.

FAQ

How do fiberglass tubes compare to steel tubes in terms of strength

Fiberglass tubes offer comparable or superior strength-to-weight ratios compared to steel tubes while providing complete corrosion immunity. While steel tubes may have higher absolute strength values, fiberglass tubes deliver equivalent structural performance at significantly reduced weights, eliminating many installation and support structure requirements. The composite construction of fiberglass tubes also provides superior fatigue resistance compared to steel alternatives.

What are the temperature limitations of fiberglass tubes versus plastic tubes

Standard fiberglass tube formulations can withstand continuous temperatures up to 200°C, while most plastic tubes are limited to 60-80°C maximum operating temperatures. High-temperature fiberglass tube variants can operate at even higher temperatures, making them suitable for applications where plastic tubes would soften or degrade. The thermal stability of fiberglass tubes also provides better dimensional stability across temperature cycles.

Are fiberglass tubes more expensive than metal or plastic alternatives

While initial material costs for fiberglass tubes may be higher than some plastic alternatives, the total lifecycle cost typically favors fiberglass tube systems due to reduced maintenance requirements, longer service life, and simplified installation procedures. Compared to metal tubes, fiberglass systems often provide cost advantages when corrosion protection, maintenance, and replacement costs are considered over the complete project lifecycle.

Can fiberglass tubes be recycled like plastic or metal tubes

Fiberglass tube recycling technologies are advancing rapidly, with mechanical recycling processes recovering glass fiber reinforcement for use in new composite products. While recycling processes for fiberglass tubes are more complex than those for metals, they are comparable to or better than many plastic recycling processes. The exceptional durability of fiberglass tubes also means they typically require replacement far less frequently than alternative materials, reducing overall environmental impact.