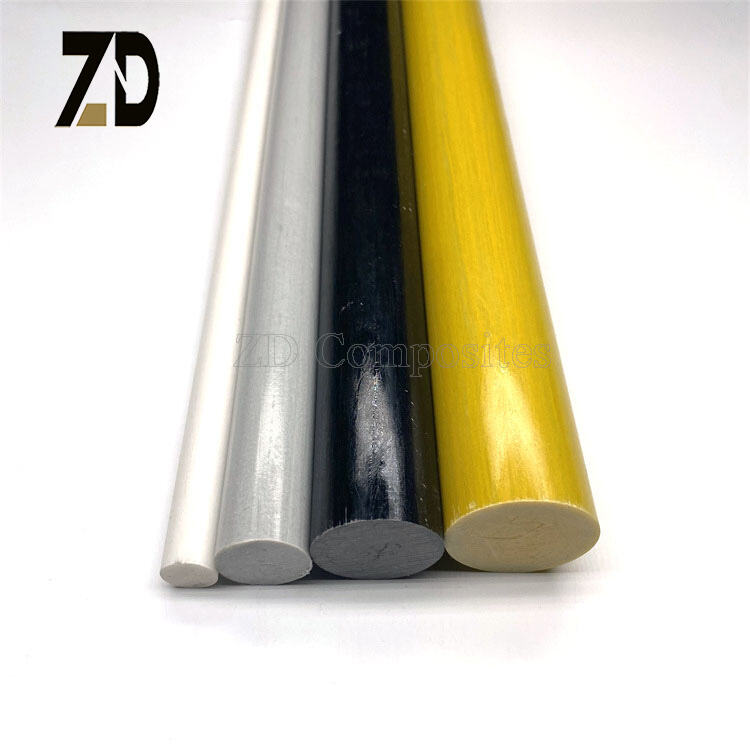

Modern landscaping projects demand durable, reliable, and cost-effective solutions that can withstand various environmental conditions while maintaining structural integrity. The fiberglass stake has emerged as a superior alternative to traditional wooden and metal stakes, offering unprecedented advantages for professional landscapers and property owners alike. These innovative support systems provide exceptional strength-to-weight ratios, weather resistance, and longevity that make them ideal for diverse landscaping applications ranging from plant support to boundary marking.

Understanding the unique properties and benefits of fiberglass stakes enables landscaping professionals to make informed decisions that enhance project outcomes while reducing long-term maintenance costs. The adoption of fiberglass stake technology represents a significant advancement in landscaping infrastructure, combining engineering excellence with practical functionality to deliver solutions that exceed traditional material limitations.

Superior Durability and Weather Resistance

Exceptional Corrosion Resistance Properties

Unlike metal stakes that succumb to rust and corrosion over time, the fiberglass stake demonstrates remarkable resistance to environmental degradation. The composite construction creates an impermeable barrier against moisture, chemicals, and atmospheric pollutants that typically cause material deterioration. This inherent resistance ensures that landscaping installations maintain their structural integrity for extended periods without requiring frequent replacements or maintenance interventions.

The non-metallic composition eliminates galvanic corrosion concerns, making fiberglass stakes particularly valuable in coastal environments where salt spray accelerates metal degradation. Professional landscapers report significant cost savings when utilizing fiberglass stakes in challenging environments, as the material maintains its performance characteristics regardless of exposure to harsh weather conditions or chemical treatments commonly used in landscape maintenance.

Temperature Stability and Thermal Performance

Temperature fluctuations that cause expansion and contraction in traditional materials have minimal impact on fiberglass stake performance. The low coefficient of thermal expansion ensures dimensional stability across wide temperature ranges, preventing the loosening or failure that commonly occurs with metal stakes during seasonal temperature changes. This thermal stability maintains consistent support for plants and structures throughout varying weather conditions.

The material composition also provides excellent insulation properties, reducing heat transfer that can damage sensitive plant root systems when stakes are placed in proximity to vegetation. This thermal management capability makes fiberglass stakes particularly suitable for supporting temperature-sensitive plants and creating microclimates that promote optimal growing conditions in landscaping applications.

Enhanced Strength and Structural Performance

High Strength-to-Weight Ratio Benefits

The engineering advantages of fiberglass stakes become apparent when considering their exceptional strength-to-weight ratio, which surpasses traditional materials by significant margins. This characteristic enables easier handling and installation while maintaining superior load-bearing capabilities essential for supporting mature plants, fencing systems, and temporary structures in landscaping projects. The reduced weight facilitates transportation and reduces labor costs associated with stake installation and removal.

Professional contractors appreciate how the lightweight nature of fiberglass stakes simplifies logistics without compromising structural performance. A single worker can easily handle multiple stakes, increasing installation efficiency and reducing project timelines. The fiberglass stake maintains its strength characteristics even when subjected to dynamic loads from wind, vibration, or ground movement.

Flexibility and Impact Resistance

The inherent flexibility of fiberglass stakes provides superior impact resistance compared to rigid materials that are prone to cracking or breaking under sudden stress. This flexibility allows the stakes to bend and flex during high-wind events or when subjected to accidental impacts from maintenance equipment, returning to their original position without permanent deformation or failure. Such resilience significantly reduces replacement costs and maintains landscape integrity during adverse conditions.

Impact resistance becomes particularly valuable in high-traffic areas where landscaping elements may encounter pedestrian contact or maintenance activities. The ability to absorb and dissipate impact energy prevents the catastrophic failures common with brittle materials, ensuring continuous support for landscape installations while minimizing safety hazards associated with broken or sharp fragments.

Installation Efficiency and Ease of Use

Simplified Installation Procedures

The installation process for fiberglass stakes requires minimal specialized tools or techniques, making them accessible to both professional landscapers and property owners undertaking DIY projects. The material composition allows for easy cutting to custom lengths using standard tools, eliminating the need for specialized metal-cutting equipment or professional fabrication services. This versatility enables on-site customization that adapts to specific project requirements without additional costs or delays.

Ground penetration characteristics of fiberglass stakes facilitate easy installation even in challenging soil conditions. The pointed tip design and material properties enable efficient driving into various soil types without pre-drilling or specialized insertion equipment. This installation efficiency reduces labor costs and project timelines while maintaining professional installation standards that ensure optimal performance and longevity.

Maintenance and Replacement Advantages

Long-term maintenance requirements for fiberglass stakes are significantly reduced compared to traditional materials, as they do not require protective coatings, rust treatments, or periodic refinishing. The material maintains its appearance and structural properties with minimal intervention, requiring only occasional cleaning to remove accumulated debris or soil deposits. This low-maintenance characteristic translates to reduced lifecycle costs and improved project economics.

When replacement becomes necessary due to damage or project modifications, fiberglass stakes can be easily removed and disposed of without environmental concerns. The non-toxic composition eliminates disposal restrictions common with treated wood or metal stakes, simplifying waste management and supporting sustainable landscaping practices. Replacement stakes can be quickly installed using the same techniques and tools, minimizing disruption to established landscape installations.

Environmental and Safety Considerations

Eco-Friendly Material Composition

Environmental responsibility in landscaping projects increasingly demands materials that minimize ecological impact while maintaining performance standards. The fiberglass stake composition contains no harmful chemicals that can leach into soil or groundwater, making it safe for use around edible plants, water features, and environmentally sensitive areas. This non-toxic characteristic supports organic gardening practices and sustainable landscape development initiatives.

The manufacturing process for fiberglass stakes typically generates less environmental waste compared to metal production, and the extended service life reduces the frequency of replacements that contribute to material consumption. Recycling opportunities for end-of-life fiberglass stakes continue to expand as the technology matures, supporting circular economy principles in landscape construction and maintenance.

Safety Features and Risk Reduction

Safety considerations in landscaping projects benefit from the inherent properties of fiberglass stakes, which eliminate many hazards associated with traditional materials. The non-conductive nature prevents electrical hazards when working near power lines or electrical systems, providing enhanced safety for maintenance personnel and reducing liability concerns for property owners. This electrical isolation becomes particularly important in commercial landscaping applications where worker safety regulations are stringent.

The smooth surface finish and absence of sharp edges reduce injury risks during handling and installation procedures. Unlike metal stakes that can develop sharp edges through corrosion or damage, fiberglass stakes maintain their smooth surface characteristics throughout their service life. This consistency in surface condition supports safe handling practices and reduces the risk of cuts or punctures during routine maintenance activities.

Cost-Effectiveness and Economic Benefits

Initial Investment and Lifecycle Value

While the initial cost of fiberglass stakes may exceed traditional wooden alternatives, the total lifecycle value proposition demonstrates significant economic advantages through reduced replacement frequency and maintenance requirements. Professional cost analyses consistently show that fiberglass stakes provide superior return on investment when evaluated over multi-year periods, particularly in applications where durability and performance are critical factors.

The extended service life of fiberglass stakes reduces the frequency of landscape maintenance interventions, resulting in lower labor costs and minimized disruption to established plantings. This longevity particularly benefits commercial properties where landscape appearance directly impacts property values and tenant satisfaction. Investment in quality fiberglass stakes often pays for itself through reduced maintenance costs and improved landscape performance.

Labor and Installation Cost Savings

Installation efficiency translates directly to reduced labor costs, as fiberglass stakes require less time and specialized equipment compared to alternative materials. The lightweight nature enables single-person installation for most applications, reducing crew requirements and associated labor expenses. This efficiency becomes particularly valuable in large-scale landscaping projects where installation time significantly impacts project budgets and timelines.

Reduced tool requirements and simplified installation procedures minimize equipment costs and eliminate the need for specialized training or certification programs. Contractors can deploy existing crews without additional skills development, maintaining productivity while adopting superior technology. These operational advantages contribute to competitive pricing advantages and improved profit margins for landscaping service providers.

Versatile Applications in Landscaping Projects

Plant Support and Growth Management

Plant support applications represent one of the most common uses for fiberglass stakes in landscaping projects, where their combination of strength, flexibility, and weather resistance provides optimal growing conditions for various plant species. Young trees particularly benefit from the consistent support that fiberglass stakes provide during establishment periods, as the stakes maintain their position and structural integrity regardless of weather conditions or soil movement.

Vine support systems utilizing fiberglass stakes create durable frameworks that accommodate plant growth while withstanding environmental stresses. The material's resistance to UV degradation ensures that support structures maintain their appearance and functionality throughout extended growing seasons. Garden professionals report improved plant survival rates and enhanced growth patterns when utilizing fiberglass stakes compared to traditional support systems.

Boundary Marking and Temporary Installations

Boundary marking applications benefit from the visibility and durability characteristics of fiberglass stakes, which can be customized with colors or markings to enhance identification and compliance with regulatory requirements. Construction and landscaping projects often require temporary boundary markers that maintain their position and visibility throughout project durations, making fiberglass stakes ideal for these applications due to their stability and weather resistance.

Temporary installation requirements in landscaping projects demand materials that provide reliable performance during short-term use while remaining easy to remove and redeploy as needed. The fiberglass stake meets these requirements by offering consistent performance characteristics and simplified installation procedures that adapt to changing project needs without compromising effectiveness or increasing costs.

Comparison with Traditional Staking Materials

Advantages Over Wooden Stakes

Traditional wooden stakes suffer from inherent limitations that fiberglass stakes successfully overcome, including susceptibility to rot, insect damage, and weathering that compromises structural integrity over time. Wooden stakes require regular inspection and replacement, often failing at critical times when plant support is most needed. The fiberglass stake eliminates these concerns by providing consistent performance characteristics that do not degrade due to biological or environmental factors.

Chemical treatment requirements for wooden stakes introduce environmental concerns and handling hazards that are completely avoided with fiberglass alternatives. The natural resistance of fiberglass stakes to decay and insect damage eliminates the need for chemical preservatives that can leach into soil or pose risks to plant health and environmental quality. This chemical-free approach supports organic growing practices and reduces regulatory compliance concerns.

Performance Benefits Compared to Metal Stakes

Metal stakes, while offering initial strength advantages, deteriorate rapidly in outdoor environments through corrosion processes that compromise both structural integrity and aesthetic appearance. The fiberglass stake maintains its original properties throughout its service life, providing consistent support without the progressive weakening characteristic of corroding metal stakes. This reliability ensures that landscaping installations maintain their intended performance levels regardless of environmental exposure duration.

Electrical conductivity of metal stakes creates safety hazards and installation limitations that are completely eliminated with non-conductive fiberglass alternatives. Lightning protection considerations and electrical safety requirements often prohibit or restrict metal stake usage in certain applications, making fiberglass stakes the preferred choice for comprehensive landscape installations. The electrical isolation properties enhance safety for both installation personnel and long-term users of landscaped areas.

FAQ

How long do fiberglass stakes typically last in outdoor landscaping applications

Fiberglass stakes typically provide service life exceeding 15-20 years in most outdoor landscaping applications, with many installations maintaining structural integrity for significantly longer periods. The UV-resistant composition and weatherproof characteristics ensure that performance degradation occurs gradually over extended timeframes, unlike traditional materials that may fail suddenly due to corrosion or decay. Actual service life depends on specific environmental conditions and application requirements, but professional landscapers consistently report superior longevity compared to wooden or metal alternatives.

Can fiberglass stakes be cut or modified on-site for custom applications

Yes, fiberglass stakes can be easily cut to custom lengths using standard tools such as hacksaws, circular saws with appropriate blades, or specialized composite cutting tools. This field customization capability allows contractors to adapt stakes to specific project requirements without special ordering or fabrication delays. When cutting fiberglass stakes, proper safety equipment including eye protection and dust masks should be used to manage any particles generated during the cutting process. The cut ends typically do not require special treatment or sealing, maintaining their performance characteristics immediately after modification.

Are fiberglass stakes suitable for use in organic gardening and food production areas

Fiberglass stakes are completely suitable for organic gardening and food production applications due to their non-toxic composition and absence of chemical treatments that could contaminate soil or plants. The inert material composition does not leach harmful substances into growing media, making it safe for use around edible plants and in areas where soil and water quality are critical considerations. Many organic certification programs specifically approve fiberglass stakes as acceptable support materials, recognizing their environmental safety and chemical-free characteristics that align with organic growing principles.

What installation tools and techniques are recommended for fiberglass stakes

Installation of fiberglass stakes typically requires only basic tools such as a hammer or mallet for driving stakes into soil, and possibly a drill for pre-drilling holes in particularly hard or rocky ground conditions. The pointed tip design facilitates easy penetration in most soil types without specialized equipment. For larger diameter stakes or challenging soil conditions, a pneumatic or electric post driver can accelerate installation while maintaining proper stake alignment. No special anchoring hardware or concrete is typically required, as the stake friction and soil compaction provide adequate holding power for most landscaping applications.

Table of Contents

- Superior Durability and Weather Resistance

- Enhanced Strength and Structural Performance

- Installation Efficiency and Ease of Use

- Environmental and Safety Considerations

- Cost-Effectiveness and Economic Benefits

- Versatile Applications in Landscaping Projects

- Comparison with Traditional Staking Materials

-

FAQ

- How long do fiberglass stakes typically last in outdoor landscaping applications

- Can fiberglass stakes be cut or modified on-site for custom applications

- Are fiberglass stakes suitable for use in organic gardening and food production areas

- What installation tools and techniques are recommended for fiberglass stakes